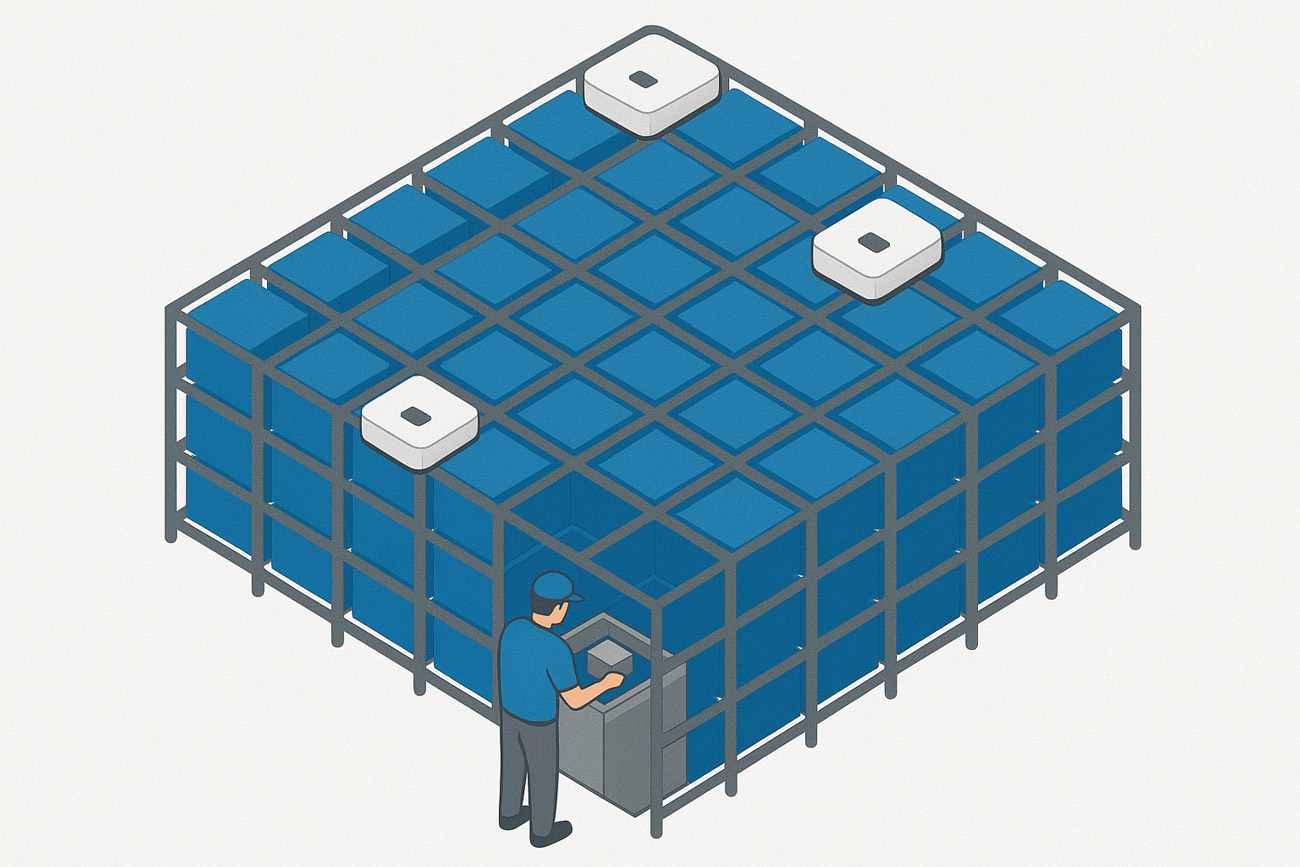

We design the Autostore system and related processes.

Autostore is the most modern and cost-effective automated warehouse system of our time. In addition to being modern, Autostore also has many specialties as a technology. Our team of experts has significant experience in designing and operating the Autostore system, and we also have direct contact with the Autostore development team, so we can answer any special questions.

Unlike installation suppliers, our goal is not to design the largest possible system, but to develop the most competitive solution for the customer. During the design, we not only design the Autostore system, but also develop the related logistics systems and processes, because the automation of logistics processes also requires the development of processes, since completely different conditions are required for a manual and an automated operation.

The cost of automation is typically very high, so the question is which processes or products can be financially justified for the development, we will also answer this based on data analysis, as we will also show if autostore is not the best solution but some other automatic or semi-automatic technology.

Our experts will map your processes in a few weeks, then based on the results of the exploration and our experience in designing an Autostore system, we will develop different development concepts for you, which best fit your processes and existing infrastructure, which we will evaluate using financial indicators. We will select the right concept together with you and help you implement it!

Why choose us when designing an autostore system?

- We have many years of professional experience in logistics and production, over the years we have designed Autostore systems in several industries, using our experience to create the best solution for you,

- We like to point out problem areas with the help of our measurement numbers and data analysis methodologies, which numbers can be used to support your investment,

- We develop several concepts with different investment cost levels, so you have the opportunity to choose the solution that best suits your company’s situation,

- We can validate the selected automation solution with the help of simulation software, we can determine the required number of robots, with the help of these models the bottlenecks and situations that arise in the event of operational disruptions become visible,

- We are not in contract with any company that distributes automated systems, so we will not recommend the solutions that are most favorable to us, but the ones that are most suitable for you,

- We calculate exact investment costs, operating costs and necessary labor requirements, based on which the exact return on the system can be determined

- In direct contact We are with the Autostore development team so we can answer any questions you may have.

Do you have any questions?

Please contact our professional manager!

Balázs Sztrapkovics

- balazs.sztrapkovics@innolog.hu

- +36 70 558 92 24

Write to Us!

Main references from this service type

Task: Design of an automated box and narrow aisle manual warehouse at an existing site, rethinking the functions of existing warehouses, and developing logistics processes.

Task: Comprehensive review of logistics processes, development of development concepts. Review of applied packaging technologies, detailed layout design of packaging cells.

Task: Possible application of certain tools of Industry 4.0 during warehouse processes, quantification of the benefits and savings that can be achieved with the introduction, and the necessary investment costs.

Task: Design of a new ~20,000 pallet automated high-bay warehouse, as well as the automated material handling system serving the plants and the track sections connecting them. Design of a picking warehouse and picking processes, validation of the designed system using a simulation model.

Task: Scheduling of a new ~20,000 pallet automated high-bay warehouse, and optimization of the entire Hungarian distribution network of Egis with the implementation of the warehouse, and determination of the necessary investments.

Task: Lean development of raw material call-out scheduling and delivery-related operations, with particular attention to the design of collective milk runs applicable to suppliers.

Task: Design of the packaging washing area and the associated automated track system for the black and white packaging warehouse of the Kisvárda plant.

Task: Design of automatic high-bay warehouses for fresh and frozen finished products and the associated automated track system, and its validation using simulation software modeling.

Task: Optimization of the plant layout, development of a plant logistics system, and development of processes in connection with the plant expansion of the Petneháza plant. The main goal is to reduce the need for live labor and explore automation opportunities.