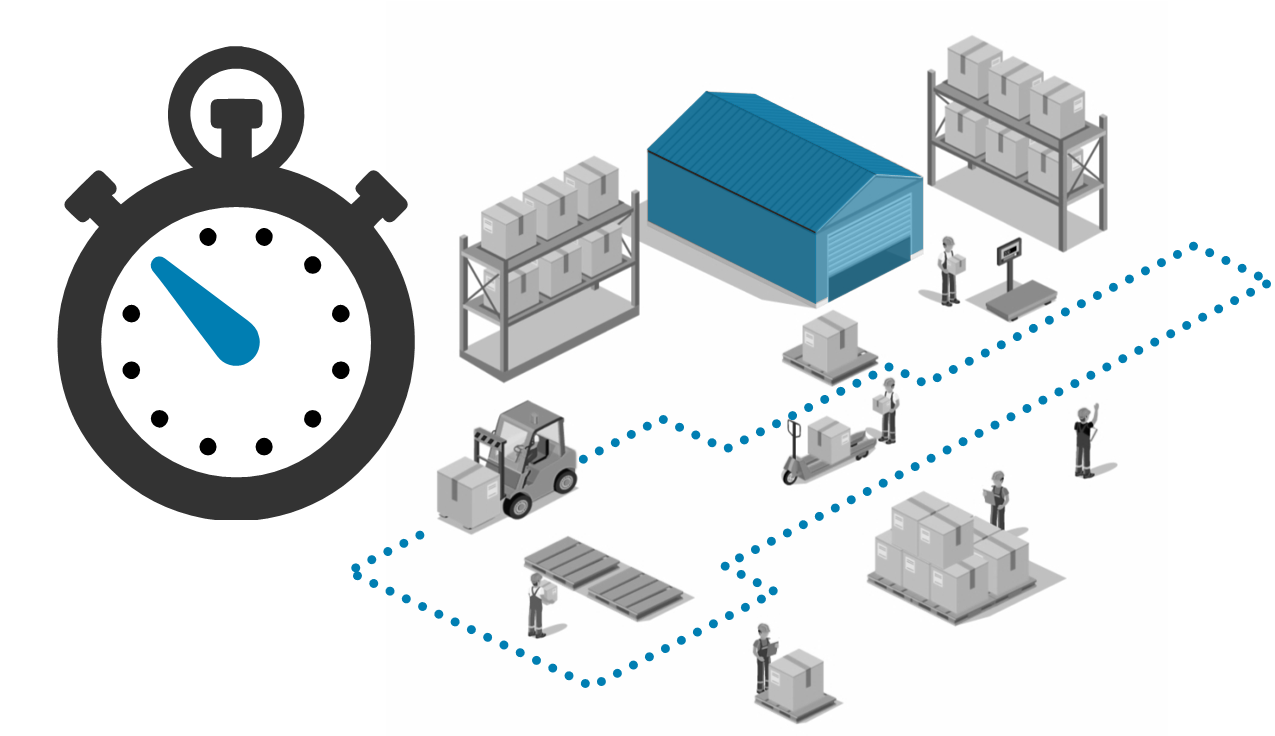

One of the foundations of production planning and cost calculations is the knowledge of the time requirements of production processes. Most manufacturing companies work on the basis of estimated, received, or possibly older analysis data, although knowing the exact time requirements is essential for planning and price calculation.

By performing multi-moment measurements, it is possible to determine how much of their working time employees spend on productive activities, and thus we can also get an idea of the efficiency of employees. Based on the measurements, it becomes possible to improve processes and determine the savings inherent in the improvements using the MTM method.

Why choose us when determining standard time?

- We point out what activities employees perform during their working hours, how much time they spend on administration, and we can quantify potential savings with the help of MTM analyses.

- We can implement the measurement at a lower cost level than if our own employees were measuring the processes (hidden cost!), and our measurements are supervised by professionals experienced in professional measurements.

- We analyze the data obtained during the measurement with modern statistical methods, we also examine correlations during the data analysis, based on which development proposals can be developed.

- As an external actor, our colleagues can objectively measure your employees, avoiding long-term sources of conflict!

- As an external actor, marking conflict points does not cause us any problems.

Do you have any questions?

Please contact our professional manager!

Balázs Sztrapkovics

- balazs.sztrapkovics@innolog.hu

- +36 70 558 92 24

Write to Us!

Main references from this service type

Task: Determination of the production standard time for the highest-selling products and measurement of employee efficiency using a sample workday survey.

Task: Determination of standard time for production and packaging processes and measurement of employee efficiency using a sample workday survey.

Task: Recording and documenting the production processes of a selected product group, then measuring the operating times of these processes and measuring employee productivity using a sample workday recording. Designating development directions based on the results.

Task: Determination of the reference times of transformer windings as a function of winding parameters, using machine times and manual measurement results. Documentation of the developed methodology and MS Excel application and training for production planners.

Task: Development of measurement and statistical evaluation know-how for determining reference times based on the welding processes of the transformer cabinet.

Task: Sampling of working days and cycle time measurements of three production lines serving as input for a simulation model.

“The INNOLOG subcontractor process measurement work was implemented as an exemplary project and partnership. In order to ensure a fast process, high availability was ensured, the defined deadlines were met, and finally a precise, valuable result material was delivered. Both the senior engineers and the measurement people demonstrated appropriate behavior and worked well and in a good mood with the Wellis employees. We hope for further successful cooperation.”