We plan your warehouse and premises based on logistical considerations.

Site planning

Our company has significant experience in designing complete sites, warehouses and production halls, but we undertake the entire design process, including the preparation of architectural plans, up to obtaining the licensed plan. We plan the site layout, transport connections, internal traffic regulations, parking lots for people and goods, and pedestrian traffic in detail. During the design, we take into account the relevant architectural and transport technology conditions (installation requirements, manipulation area requirements). We pay special attention to ensuring that the new site serves production and logistics processes as much as possible. In other words, we adapt the site to the processes and not the processes to the site!

Plant Planning

We undertake the planning of industrial and production plants, in which, besides the architectural aspects, we take into consideration the needs and peculiarities of the operational and logistical processes of the plant. Our goal is not to adapt the processes to the building, but to adapt the building to our processes. During the planning process, we optimize the internal layout of the plant, and then we start sketching and detailed planning of the building and other facilities.

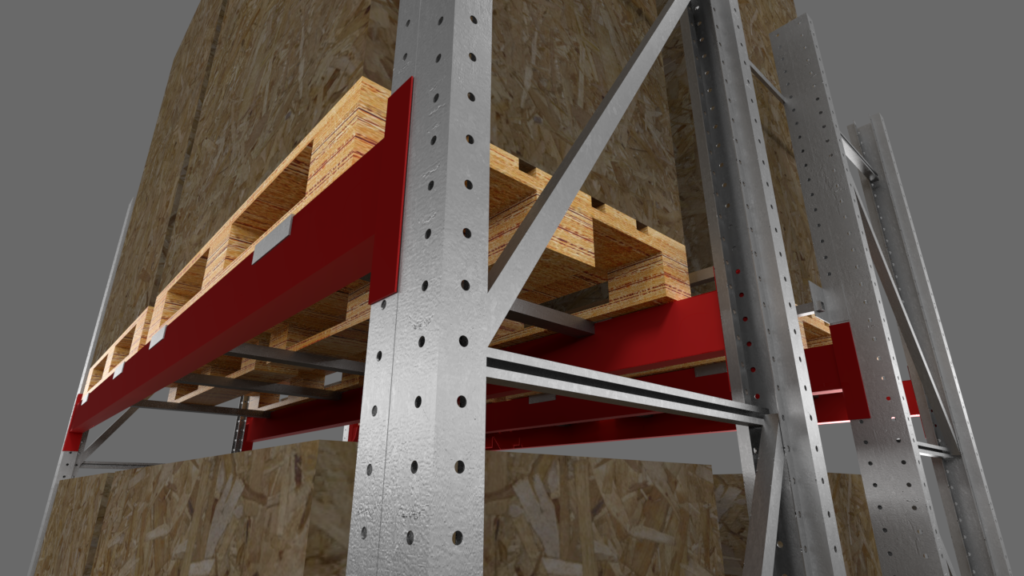

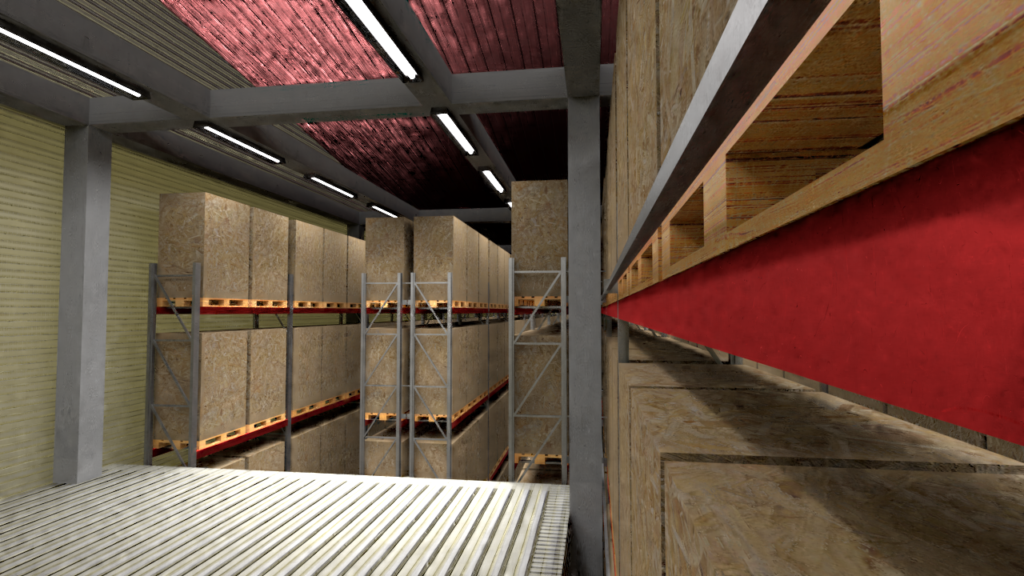

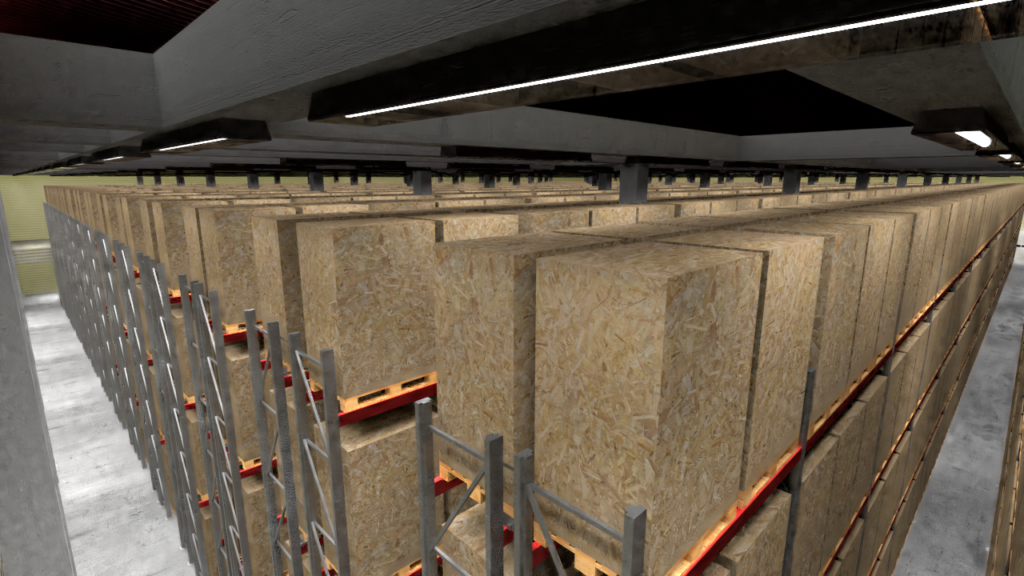

Warehouse Planning

Establishing an appropriate warehouse structure is essential for efficiently serving the needs caused by the on-site logistics processes. In case of greenfield warehouse planning projects, it’s often a problem for companies, that the newly built facility can prevent the implementation of the required system.

To remedy this, we assess and plan the expected logistics processes already during the pre-planning phase, select the required storage technology, material handling machines, and then the final plans are prepared according to these.

Why choose us for site and warehouse planning?

- As an independent expert, we can offer the best warehouse technology solutions, as we are not contracted with any warehouse equipment supplier.

- Logistics system design requires expertise and experience, so it is advisable to entrust this task to a specialist with sufficient expertise in the field of logistics.

- In order for the company to select the right warehouse technology solution, it is worth considering the full range of options, for which it is advisable to use the help of an external, objective expert.

- We seek and believe in shared successes. In this spirit, we develop solutions in close cooperation with colleagues.

- We provide complex solutions with precise planning from the moment the need arises to the “cutting of the ribbon”,

- We have many years of experience in cooperation with other fields necessary for the design of warehouse buildings, halls and sites.

Do you have any questions?

Please contact our professional manager!

Balázs Sztrapkovics

- balazs.sztrapkovics@innolog.hu

- +36 70 558 92 24

Write to Us!

Main references from this service type

Task: Development of warehouse layout and material flow processes and technological options along multiple objective functions such as maximum material flow efficiency, maximum storage capacity, and minimum investment requirements.

Task: After recording the status of the logistics processes provided by Ghibli Ltd. to Siemens, to identify and quantify the bottlenecks in the system. The goal is for Ghibli Ltd. to become a JIT supplier to Siemens.

Task: Complex brownfield warehouse planning and full management and execution of the central warehouse relocation.

“During the project to develop our new warehouse base, IdeaLog specialists provided professional and high-quality services throughout. It was very important for us that we were informed about every step of the project in a timely manner, they constantly communicated with colleagues, managed the processes, and we were able to discuss each milestone together, both in terms of tasks and costs. They became real colleagues during the project, who not only looked at the processes from the outside but also actively participated from the inside in order to achieve the jointly dreamed goal.”

Gábor Kiss

KONE Elevator Ltd.

Regional Economic and Procurement Manager

Task: Develop a warehouse expansion layout plan, develop storage logic, and prepare process specifications to enable the implementation of a WMS system in warehouse processes.

Task: Initiating a lean approach and mindset shift, as well as the lean development of the logistics system of the central, cross-docking site, and the elimination of process elements that cause losses.

Task: Layout and process design of the new logistics processes related to the relocation of the central cross-docking warehouse.

“The work that the Lean colleagues did greatly helped to increase the efficiency of our operational processes. The principles they formulated can be easily transferred to daily practice, thus increasing the level of service provided by our company. We look forward to their work in the future!”

László Kis

trans-o-flex Hungary Kft.

Logistics Director